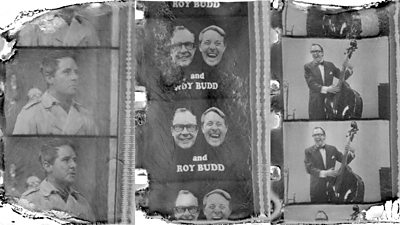

In the we brought you the story of how a badly deteriorating film copy of a episode of Morecambe and Wise’s first �������� TV series from 1968 was found rotting away in a vault in Nigeria. The hunt was on for a way to get the programme off the film without unwrapping it as it was too brittle.

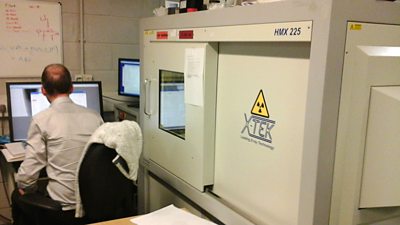

In today’s instalment we bring on the lasers and X-ray... As mentioned in the previous post Dr Graham Davis, Professor of 3D X-ray Imaging at Queen Mary University of London, had been recommended as someone who might be able to help - though scanning every layer of a reel of film without unwrapping it was probably going to prove impossible... and here he describes how he went about it.

I have been working on X-ray microtomography (aka micro-CT or XMT) at Queen Mary University of London since around 1990, and am particularly interested in designing scanners that could detect very small differences in mineral content in bones and teeth. Though working in the Institute of Dentistry, encounters with experts in other fields led to all kinds of “off-piste” research, particularly work on reading historic scrolls that had become fused together and could not be unrolled; a project that saw David Mills join the team. We had occasionally considered the possibility of imaging film negatives, but had never got around to trying it. In theory, silver should show up very well in X-rays, having a higher atomic number than the iron we were detecting in the iron gall ink on the scrolls. When Charles enquired about scanning a reel of film, I was confronted with an immediate problem: with tomography you can get high resolution with small objects, or coarse resolution with large objects. If you want to get high resolution with large objects you are up against the fundamental laws of physics, and they don’t budge. But this was Morecambe and Wise, so we had to figure out just what we could achieve within the laws of physics and capabilities of current technology.

The first step was to try scanning something smaller with our existing custom designed scanner, known as MuCAT 2. I asked Charles if he could supply some relatively worthless black and white film for us to play with and he supplied a copy of a German version of Snow White on 8mm film. Initially we tried X-raying an open section of the film which, disappointingly, only revealed a very vague impression of the film image. With little hope of getting any further, we performed a tomographic scan on a rolled length of the film inside a 30 mm diameter plastic container; around a tenth of the diameter of the Morecambe and Wise film.

The result was quite surprising. The silver images showed up very clearly in the 3D volume, although slicing through the volume only gave us views cut across many layers of film and we could not at that time virtually unroll it. Tomography produces images made up of 3D pixels called voxels - imagine a massive cube made up of different coloured sugar-lumps. It’s easy to split that image up by slicing along the surface of the sugar lumps, but following a curved surface like a film reel is much harder.

Project partners at Cardiff University had already written code to read text on rolled scrolls, but the principle of virtually unrolling a film is very different from unrolling a parchment scroll. For scrolls, you detect the surface of the parchment and then look for ink on this surface. With a tightly wound film, there is no discernible gap between the layers and thus we needed a new approach that relied on tracking the surface by tracing the silver image itself. Since we were trying to prove feasibility at this stage, I wrote a simple program that could track the image, relying heavily on the fact that this film was wound in an orderly manner. This was surprisingly successful in unravelling the film, and a second program used images of the sprockets along the edge of the film as reference markers to divide the film into individual frames before transforming them into a movie. To our knowledge, this was the first time a film had ever been viewed without physically unrolling it - though of course in this case that was still an option.

Spurred on by our success, we scanned a second film featuring the opening sequence of the Gaumont British News, rolled up inside a plastic 35 mm film canister. In this case, I was also able to re-create audio from the optical sound track that ran along the side of the images. This 12.5 second video clip was a remarkable demonstration of just what the technology could achieve and was hailed by many as being nothing short of miraculous. But, not wanting to give false hope, I was keen that it should be seen as nothing more than a limited demonstration and not a solution to a problem; unless anyone had a 30 mm diameter film roll they needed scanned.

In order to get a reasonable image from the film, we needed a scanning resolution (voxel size) of 20 µm (millionths of a metre). Thus, a 30 mm diameter film reel is 1500 voxels across. A 300 mm diameter reel would be 15,000 voxels across. The Morecambe and Wise film exceeded this dimension in places, probably requiring around 20,000 voxels. Technologically, a detector with sufficient resolution could be created, but this is not the fundamental problem. The physical/mathematical laws dictate that if the size is increased by a factor of n, the number of X-ray photons required for a given image quality (signal-to-noise ratio) must increase by a factor of n4 (n×n×n×n). Thus, an increase in size by a factor of 10 (10×10×10×10) would require 10,000 times the number of photons. This could possibly be provided with a synchrotron X-ray source (a large machine about the size of a football field), but no detector exists that could cope with that massive exposure. An X-ray beam that intense would also generate enough heat to incinerate the film. Oil cooling might help, but the whole film would have to be dimensionally stable to around 1 part in 40,000. After these sorts of back-of-envelope calculations, I confronted Charles with the prospect that this could not be done. Even if (a very big “if”) we could conceive of building an entirely new type of imaging system at a synchrotron, it would take three to five years to get it funded and built; by which time the film would be soup. The only other option was to chop it into manageable pieces; a suggestion I did not think would be terribly palatable.

Charles was faced with cutting the last remaining record of this episode into little bits, or else letting it decay into goop. Seemingly with no hesitation, he opted for the former option and plans were rapidly put into place for Queen Mary to work with the �������� to restore images from the film. Since mechanical cutting would disturb the “Marmite” it would have to be cut with a laser. I asked Charles if he could track down such a facility and he did; in our own engineering department.

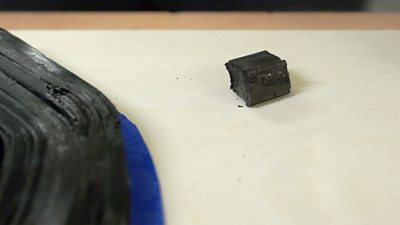

From my calculations, I knew the largest bit of film we could scan was about 2.5 cm square in cross section (this would cover two frames with a bit to spare), so the laser cutter was programmed to cut this on a sheet of wood marked out with the dimensions of the roll of film as a sanity check – we didn’t want to accidentally cut the wrong way across the film roll. We then lined the film up with the marks on the wood to get the placement correct. The laser cutter can also do a “dummy run” with a visible red laser, before firing up the high power infra-red one.

Laser cutters work by burning away a thin line of material, leaving the object in two or more separate pieces. This does cause some localized heating and damage – not ideal with historical artifacts. There was a sense of trepidation in the air as we gathered around the laser cutter, about to destroy the film.

The film, being very damp due to its acidic degradation products, gave off a worrying amount of smoke and steam as the laser hit it. Initially, we had to perform several passes of the laser over the same area to finally get the section free. Charles examined the freed block of film and declared it relatively undamaged.

At one point, after we had cut several sections, the laser caused a loose bit of film to catch fire. Charles was standing by with a fire extinguisher for just this eventuality, but didn’t need to douse the film. We shut the laser off and the flame vanished immediately.

Although our tomography system may be cutting edge, this is one area where current technology could offer a substantial improvement. A femto-second (0.000000000000001 second) pulsed laser ablation system uses very short laser pulses such that almost no heat is generated in the cut object. We are still trying to track down such a facility for future work, but for now we continued to cut the film without serious incident. Each cut block was wrapped in cling-film, labelled and placed in a refrigerator awaiting its time to be scanned.

The film blocks were placed in the scanner and the voltage was set to 40 kV, a value which produced optimal contrast. Over 5000 X-ray images were taken as the block was rotated around 360 degrees, taking around 18 hours per scan to obtain the required image quality. Once complete, the 5000+ images from the blocks of film we had cut were reconstructed in 3D (a complex mathematical process) to compile ‘virtual’ chunks of the film reel. Flicking through the images, you might see part of Eric’s glasses, or a hand, but never a whole image because of the film curving and distortion.

To get our first glimpses of whole images, I wrote a fairly basic program that could manually warp a layer through the 3D volume to follow the contours of the film. The flattened images showed varying signs of degradation and in some cases laser damage, but considering they had been raised from the dead, they really weren’t bad. Until that point, I had had some doubts about the value of what we were trying to achieve, after all, we could never restore the film in all its glory, but only capture stills and maybe put together a short video clip. But as soon as Eric and Ernie’s faces and stereotypical poses began to appear, a huge grin spread across my face and I knew that this was a job worth doing. Much as I would have loved to continue dabbling with the film recovery software forever, this was not really my area of expertise; plus, this was only supposed to be a short departure from my dental research. At this point it was time to hand the task over to the boffins at �������� Research and Development to work their magic.

- (for now!) will look at how �������� R&D have helped 'wnwarp' the recovered images and try to address the quality problems caused by the deteriaton of the film...